You have no items in your shopping cart.

Eurotherm 3216 and the Plastic Chiller Market

Monday, July 18, 2016 2:43:00 PM America/New_York

The Eurotherm 3216 has been implemented as a Chiller controller in the USA plastic market with much success.

Below is a list of the 3216 features:

1. The model 3216 has only a 90 mm depth, which allowed chiller manufacturers to have easy installation.

2. Configure of the 3216 controlleris made easy by a text display, So the user can scroll to a parameter and just a few seconds, the text display begins scrolling in marquee fashion with a description of that parameter.

3. Ordering, maintenanceand configuration have been simplified to the use of a mere 10-digit code that completely specifies the functionality and configuration.

4. Event Messages and Custom alarm can be created and loaded into the 3216.

5. The Eurotherm 3216 can replace the external timer.A timer can be used to put the unit into standby while the system is purged. Most OEMs use an external timer today, so with the 3216, a timer is not needed

6. Digital Communication is also a needed feature when selling to Chiller OEMs, and the Eurotherm 3216 meets that need.

Plastic Chiller Overview

A chiller commonly represents a small fraction of the cost of the processing equipment, yet it provides solid protection of your investment, 24-hours-a-day, and 7-days-a-week for years and years to come.The most compelling reason for a chiller in the plastics market is the protection it provides for your valuable processing equipment—such as extrusion, injection molding equipment and other applications. To increase production is another reason to use a chiller as you maintain a constant and proper cooling temperature in the equipment. A chiller will reduce the number of rejected parts while increasing the number of parts produced per hour.

A chiller is a compressor based cooling system that is similar to an air conditioner except it cools and controls the temperature of a liquid instead of air. The other main components to a chiller are a temperature controller, a recirculation pump and a reservoir. The operation and setup are simple. Fill the reservoir with fluid to be recirculated, typically water or an ethylene glycol/water mix. Install plumbing between the chiller and the application and provide power to the chiller. The controller regulates the chiller’s functions. The chiller will provide a stable flow, temperature and pressure once it has been programmed by a user. Harmful particles are kept out of the system by an internal strainer.

There are three (3) types of chillers.

An air-cooled chiller where the chillers absorb heat from process water and can be transferred to the surrounding air. Air-cooled chillers are generally used in applications where the additional heat they discharge is not a factor. They require less maintenance than water-cooled units and eliminate the need for a cooling tower and condense water pump. They generally consume approximately 10% more power than a water-cooled unit as a wet surface transfer’s heat better than a dry surface.

Second is the portable chiller, which is a liquid cooling system on casters that can be relocated from one application to another with relative ease. It can be used to cool one or more heat generating devices.

Finally, we have water-cooled chiller, which absorb heat from process water and transfer it to a separate water source such as a cooling tower, river, pond, etc. They are generally used for large capacity applications, where the heat generated by an air-cooled chiller creates a problem. Water-cooled chillers are also considered when a cooling tower is already in place, or where the customer requires optimum efficiency of power consumption. They require condenser water treatment to eliminate mineral buildup. Mineral deposits create poor heat transfer situations, which reduce the efficiency of the unit.

Summation

The Eurotherm 3216 is being used more and more to replace several interconnected devices to chillersand consolidate functions. The level of functionality, alarmingand programmability gives the user a way to create a local custom alarm strategy that can best achieve the operating safety of the machine that will help improve qualityand minimize downtime.

Switching from a 2400 Controller to a 3500 is a Snap!

Thursday, July 14, 2016 6:17:00 AM America/New_York

A 3500 series controller fits perfectly in a 2400 series case. If you are interested in taking advantage of many of the FREE software features in a 3504 or 3508 controller, you don’t even need to unwire a thing. The 3508 and 2408 cases are interchangeable. There is no difference in terminal layout and the case length is identical. The 3504 and 2404 cases are also interchangeable. However, adding the 3504 instead gives you the ability to add more IO modules. The price point between the 3500 unit and the 2400 unit is very similar and we are happy to work with you in price competitive situations.

Here are some of the free features found in a 3500 series unit not found in a 2400 unit:

- Temperature and atmosphere control in one unit

- 50 ramp/soak programs (max of 20 in the 2400 series)

- Logic and math function blocks

- Automatic thermocouple burnout switching

- Custom interface screens

Obsolete Products

Monday, June 27, 2016 1:49:50 AM America/New_York

At Eurothermonline.com we do the very best to provide you with an economical repair or replacement of all obsolete Eurotherm Instruments.

Obsolete Products

Do you have or need to replace any of the following Eurotherm or Barber Coleman instruments?

Eurotherm Ampstacks, EM1, TE10A, 91,92, 94, 808, 847, 818, 818P, 902, 903, 904, 2116

Barber Coleman 520, 570

While we do not list all of the obsolete instruments, we do provide repair, refurbished or replacement for almost all Eurotherm & Barber Coleman products.

Plus we also provide repair & replacement for most Red Lion instruments as well.

If you need over the phone or email assistance selecting a particular instrument replacement, our Engineering Specialist, Ben Hill is available ben@peproducts.com or 800-849-5655.

Allow us to help you with your obsoleted Instruments

Do you need your current product repaired or replaced?

Repair of existing products

Eurotherm Mini8 Loop Controller

Friday, June 17, 2016 7:55:13 AM America/New_York

The Mini8 controller is the ideal partner to a programmable logic controller (PLC); able to multi-drop on either Serial, Fieldbus or Ethernet communications. It offer s a real, cost-effective alternative to performing analog measurement or loop control in a PLC.

The Mini8 Controller offers high performance control usually only found in Eurotherm panel mount PID controllers.

From simple to complex, it is a compact data acquisition device also a very competitive.

Its modular design enables its I/O and feature set to be selected to cater for a wide range of applications.

The feature set of the Mini8 controller includes high performance PID control, graphical wiring and setpoint programming functions together with math, logic and timing function blocks.

It often allowing a lower specification processor to be used, because it implements these functions in the Mini8 controller reduces the hardware cost of the PLC, relieving it of the burden of performing analog functions.

When used in a data acquisition installation the high density analog I/O can be combined with paperless graphic recorder products to provide unsurpassed local and network access to your process.

7100L Single Phase Solid State Contactor

Thursday, June 9, 2016 7:38:28 AM America/New_York

- Current range: 16-100A at 45°C, Voltage up to 500V

- High reliability with no mechanical contacts

- Optimized design for reduced size

- Simple installation and maintenance

- Fast cycle times give increased heater life

- Protected against transients

Economic solid state contactor for use with the low temperature coefficient loads.

The 7100L range provides an effective replacement for electromechanical contactors.

There are no mechanical contacts to wear out and so maintenance costs and downtime are reduced.

Silent operation and lack of electrical interference, achieved by zero voltage switching, give environmentally friendly operation. Fast switching reduces the thermal cycling of the elements resulting in improved control and extended element life.

Fusing

High speed fuses are external to the unit and can be ordered complete with fuse holder as part of the 7100L order code. Spare fuses or complete fuse and fuse holder assemblies can also be ordered separately

Inputs

Firing is ON/OFF in response to the logic input, with zero voltage switching. A green ‘heat’ LED indicator on the front face indicates the status of the input signal.

These units, with integral heatsinks, are driven by a logic input signal which can be either AC or DC.

Eurotherm provides very accurate indication of temperature and process measuring instruments:

Thursday, June 2, 2016 5:01:43 AM America/New_York

1/16 Din: 3216i

1/8th Din: 32h8i

1/4 Din: 3204i

The 3200i range of Eurotherm indicators offer accurate indication of temperature and process measurements. Process interlocks, including over-temperature furnace limits, are implemented using relay output channels.

The Eurotherm emphasis is on ease of use. A simple ‘Quick Start’ code is used to configure all the functions essential for indication and protecting your process.

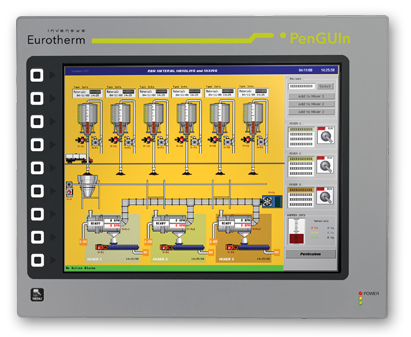

PenGUIn™ – the ultimate machine-HMI functionality

Tuesday, May 17, 2016 8:56:39 AM America/New_York

The PenGUIn machine-HMI clearly distinguishes itself in the market place through a powerful combination of monitoring, control and outstanding communication capabilities. Besides the standard HMI functionality, it includes protocol conversion, port sharing and web server capability.

All these impressive features are easily configured and managed by GUIcon software package, which includes an extensive library of more than 5000 objects. Add to this, a strong sales team comprised entirely of degree qualified engineers who understand your process, an absolute commitment to innovation, and 5% of our total sales continuously re-invested in research and development, we can and do imagine making the impossible possible for our customers.

Choose from a list with over 200 drivers for a variety of devices. Communicate with up to 13 of them SIMULTANEOUSLY and access them REMOTELY. FEATURES:

- Convert over 200 protocols

- Built-in web server

- Two Ethernet ports

- Two USB ports

- Remote monitoring & control

- Free software and support

The Solution That Will Help You To Save Money!

Wednesday, May 11, 2016 8:18:55 AM America/New_York

Mechanical contactors controlling heating elements may operate three million times per year. The lifetime of these contactors is between 1 and 3 years; therefore they need to be replaced regularly during the typical life of an industrial machine.

ESwitch is an interesting solution to solve this problem. Because the contact is electronic, the lifetime is significantly extended. Its wiring is as simple as for a mechanical contactor and the mounting is very easy: just clip it on a DIN rail! It features a broad range of AC and DC command signals with a front face LED to display the input status to help commissioning and diagnostics.

Extend the life of your heaters Tests performed by a well-known heater supplier have shown that heaters can last up to seven times longer when used with a solid state contactor. Faster on/off cycle times cause less thermal expansion and contraction and thus reduce breakage due to fatigue and thermo-mechanical stress. So by preserving the heating elements, ESwitch will allow you to maximize your ROI:

- Increase lifetime of heating elements

- Reduce downtime

- Minimize scrap

- Improve yield and productivity

By combining robustness, security of operations with simplicity of integration and use, ESwitch offers the best ratio of 'performance versus price' for the power switches market.

Ideal for

- Injection molding

- Thermo-forming

- Multi-zone heating

- Autoclaves

- Ovens

Features and Benefits of Mini8 Loop Controller

Friday, April 29, 2016 2:47:56 AM America/New_York

Most devices used to control different aspects of an industrial process or a machine for that matter, have a definite purpose to serve. The Mini8 Loop Controller is one such device, which is the pre-configured variant of multi-loop controller. So, it has taken certain features from the other version, but there are certainly several differences. It functions to control eight different temperature zones with each of them configurable as heat-cool or only heat.

The Mini8 Loop Controller is a data acquisition device that is both compact and competitive. It comes with a modular design and this is what enables the selection of its feature set and I/O for so many different applications, both complex and simple.

The Mini8 works really well with a programmable logic controller or PLC. The device allows the implementation of certain functions that helps in reducing the cost of PLC hardware, taking the burden of performing analog functions away from the PLC.

If we compare its performance with other similar devices, then it will be put in the same bracket as Eurotherm panel mount PID controllers. The device includes a feature set that comprises PID control, set point programming, and graphical wiring amongst others.

How Effective Are Eurotherm Temperature Control Solutions?

Friday, April 29, 2016 2:43:37 AM America/New_York

When it comes to buying temperature control solutions, you cannot take any chances. As temperature control solutions play a vital role in improving product quality and process efficiency, it is imperative that you should get state-of-the-art temperature control solutions installed in your facility.

Eurotherm temperature control solutions are specialized products for manufacturing and process control instrumentation. These temperature control solutions are based on highly accurate PID algorithms and data management strategies, which minimize the waste in your facility, save you lots of money, improve quality, and ensure data safety till the time it is required.

With a versatile range of temperature control products available at disposal, you can easily find different solutions to different process related issues. In this category of products, you will have devices like single loop controllers, multi-loop controller, indicator and alarm units, and special software in your arsenal to improve process functionality and limit errors. These products serve food, chemical, packaging, and pharmaceutical industries and many more. All these products are rich in features and designed to offer easy operation and reduced engineering time. What’s more; these temperature solutions come with market’s leading algorithms and recording & data management strategies that add value to many industrial processes.