You have no items in your shopping cart.

Eurotherm 1/8 DIN 2108i Horizontal Mount Indicator and Alarm unit

Wednesday, December 14, 2016 1:16:52 AM America/New_York

The Eurotherm 2108i horizontal mount indicator and alarm unit provides accurate measurement and display of temperature and other processing variables in a standard 1/8 DIN panel format. The two alarm relay outputs are provided for an operator alert and process protection.

A universal input allows selection of nine internally stored thermocouple types. Other input linearization may be factory downloaded. Linear, process inputs are scalable to the desired range. Keylock and passwords prevent unauthorized access to configuration and alarm settings.

A large, red, or green LED display gives good visibility in low and high ambient lighting.

New alarms can be acknowledged and old alarms reset by a front panel button or an external contact closure input.

Three internal alarm setpoints are provided. They are configurable as high, or low, or rate of change alarms. Any combination of these three internal alarms can activate the two relay outputs. Latching or non-latching operation can be selected and alarm delays can be applied. A special mode known as “alarm blocking” is available. In this mode, after power on, the process value must first enter a good state before the alarm becomes active. This is particularly useful for low alarms which can be “blocked” while the process is warming-up.

Calibration accuracy is preserved with a self-correcting input circuit, while a User Calibration facility allows offsets to be applied to compensate for sensor and other system errors.

Tuning Eurotherm 2208e 1/8 DIN Controller

Wednesday, December 21, 2016 1:25:00 AM America/New_York

The method for automatic tuning automatically determines the value of the parameters listed in table 4-1 in the image above. The 2208e and 2204e uses a “one-shot” tuner in which works by switching the output on and off to induce an oscillation in the measured value. From the amplitude and period of the oscillation, it calculates the tuning parameter values.

If the tuning process cannot tolerate full heating or cooling being applied, then the level of heating or cooling can be restricted by setting the heating and cooling power limits in the Output list. However, the measured value must oscillate to some degree for the tuner to be able to calculate values.

A one-shot Tune can be performed at any time but normally, it is performed only once during the initial commissioning of the process. However, if the process under control subsequently becomes unstable (because its characteristics have changed), you can re-tune again for the new conditions.

It is best to start tuning with the process at ambient temperature. This allows the tuner to calculate more accurately the low cutback and high cutback values that restrict the amount of overshoot or undershoot.

Efit SCR Power Controller

Wednesday, December 28, 2016 1:30:00 AM America/New_York

The Eurotherm EFit power controller is easy to commission and integrate. It is cost effective, but don’t provide any compromise in the control of resistive and infrared heating elements.

Cost effective and exceptional process performance

EFit is compliant with international standards of immunity, quality, and emissions, and can be used for all heating applications. The unit delivers precise control even in the most extreme industrial conditions, such as limited cabinet space.

Perfect for simple heating applications

Heat treatment and other such industrial processes need accurate temperatures to comply with regulations. However, this isn’t possible to achieve in a large industrial plant where fluctuations in voltage is a common phenomenon. If we consider resistive heaters, 20% variation in the power to the load can be caused with a variation of 10% in the supply voltage. This can cause unwanted temperature fluctuations. The EFit power control unit continues to deliver a uniform flow of power supply, even when there are voltage fluctuations. This will result in a continuous and reliable heating process that delivers products that comply with heat treatment standards.

Easy Installation

- Minimal connection — pre-wired plug in connectors

- Nothing to fix — just clip onto DIN rail

- Nothing to configure — plug and play

Control precisely

- Eliminate voltage fluctuations

- Achieve tight tolerances

- Optimize energy use

Improve processes

- Minimise downtime

- Maximise throughput

- Reduce cost of ownership

These Products Are Now Obsolete!

Thursday, January 5, 2017 1:31:00 AM America/New_York

Below are some of the Instruments or Controls that we can repair or refurbish. Need your current product repaired? Allow us to help you with your Eurotherm Obsoleted Instruments by providing replacements, refurbished units or by repairing your instrument.

- HEATSK-DIN-1.0

- I.O.-JUMPER-010

- I.O.-MARKER-011

- IO-IAC/+RO/280

- IO-IDC/+RO/28

- RSAA-660/50/10

- RVA3-6V75T/H

- SVAA-3V10

- SVDA-3V10

- SVDA-3V25

- SVDA-3V75

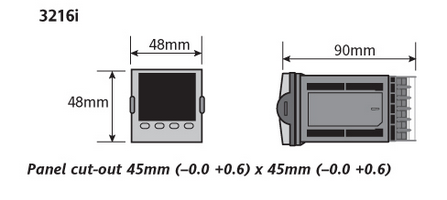

Eurotherm 3216i

Thursday, January 12, 2017 1:34:00 AM America/New_York

The Eurotherm 3216i indicators offer accurate indication of temperature and process measurements. Process interlocks, including overtemperature furnace limits, are implemented using relay output channels.

Industrial environments can do with instruments with simple usage. The same is available with Eurotherm 3216i and other indicators in this range.

Whether it concerns the indication of the breach of set limits or the protection of your process, you can use the 'Quick Start' code configure all the functions as you need them. When you need to implement process interconnections like over temperature furnace limits, you can use the provided relay output channels.

Uses:

Plastics - extrusion melt pressure

Level/pressure/flow

Weighing platform

Heat treatment - furnace over temperature

Temperature & process indication

Process protection

Eurotherm 32h8i

Thursday, January 19, 2017 2:12:00 AM America/New_York

The Eurotherm 32h8i indicators offer accurate indication of temperature and process measurements. Process interlocks, including overtemperature furnace limits, are implemented using relay output channels.

It is all about how conveniently the device can be used. The user can configure every function based on the needs of the process with the 'Quick Start' code. Indications have to be defined to set process limits.

Eurotherm 32h8i indicator and others in the 3200i series precisely indicate process and temperature measurements. Relay output channels are used to implement over temperature furnace limits and other process interlocks.

Best for:

Weighing platform

Temperature & process indication

Plastics - extrusion melt pressure

Process protection

Level/pressure/flow

Heat treatment - furnace over temperature

Eurotherm 2132i

Thursday, January 26, 2017 2:18:49 AM America/New_York

A universal input enables selection of nine internally stored thermocouple types and the PT100 resistance thermometer. Linear inputs can be scaled to the desired display range. Two relay outputs are configurable for alarms. Three internal alarm setpoints are provided- configurable as high, low or deviation. Alarms can be 'blocked' on start-up to prevent unnecessary operator alerts.

The 1/32 DIN Eurotherm 2132i temperature and process controller comes with indication and alarming capabilities. Relay outputs can be used to implement over temperature furnace limits and other such process interlocks.

Fully configurable using operator interface

Alarm blocking on start-up

Simple operation

Reliable performance and accuracy

The PT100 resistance thermometer and nine thermocouples that are stored internally are available for selection with the universal input. Users can download other input linearizations. Based on the display range, linear inputs can be scaled accordingly.

There are three internal alarm set points that can be configured as deviation, high, or low alarms. Users can block the alarms on start-up to avoid unwanted alerts.

Users can expect positive operation with the presence of tactile buttons.

Based on the parameter the operator wants to see and adjust, the operator interface can be accordingly customized. Other parameters can be put under password protection.

Ideal for:

Plastics - extrusion

Heat treatment -small ovens

Sterilizers

Chillers

Trace heating

Heat sealing

Features:

Three internal alarm set points

Two configurable outputs

Universal input selection

Heater failure detection

Customized operator interface

Tactile buttons

PenGUIn™ machine-HMI (PG10)

Friday, February 3, 2017 6:10:32 AM America/New_York

The PG10 Operator Interface Terminal combines unique capabilities normally expected from high-end units but at a very affordable price. It is built around a high-performance core with integrated functionality. This core allows the PG10 to perform many of the normal features of the Paradigm range of Operator Interfaces while improving and adding new features.

The PG10 can communicate with many different types of hardware using high-speed RS232/422/485 communications ports and Ethernet 10 Base T/100 Base-TX communications. In addition, the PG10 features a USB port for fast downloads of configuration files and access to trending and data logging. A CompactFlash socket is also given so that Flash cards can be used to collect your trending and data logging information as well as to store larger configuration files.

In addition to accessing and controlling external resources, the PG10 allows a user to easily view and enter information. Users can enter data through the touchscreen or front panel 8-button keypad.

Eurotherm NANODAC

Friday, February 10, 2017 6:27:00 AM America/New_York

The Eurotherm nanodac™ provides the ultimate in graphical recording combined with PID control and setpoint programs.

The compact ¼ DIN panel mount unit offers four high accuracy universal inputs for data recording and PID control. It is a secure data recording device with accurate control and is enhanced by a full color, ¼ VGA display which brings a crystal clear operator interface to even the smallest of machines.

YouTube video https://www.youtube.com/watch?v=ufDyyx9P7N4

PID Control Loops

The nanodac™ instrument can also provide two independent control loops (optional). This control functionality utilizes the advanced Eurotherm PID algorithm providing high performance and reliability to your process. It has one of the best auto-tunes facilities available along with overshoot inhibition (cutbacks); compensation for power fluctuations using power feedforward; linear, fan, oil and water cooling.

In the Heat Treatment processes set-points often need to vary control process over a set period of time. So this is achieved by using a set-point program.

The nanodac™ offers an optional Dual Programmer supporting up to 100 programs locally, each program supporting 25 segments.

The nanodac™ also provides remote access to a further 100 programs that can be easily retrieved via FTP or USB memory stick.

Ther display is crystal clear

The 3.5” TFT display offers incredibly clear visualization of process parameters with a wide selection of configurable views to best suit the application. You gave the following views: Numeric; Horizontal and vertical trends; Horizontal and vertical bar graphs; Alarm panel, Alarm status, and control loops. User wiring from the front of the product, provides for detailed configuration without the need to connect to a PC.

Wash down Front

An optional IP66 rated Wash-down bezel has been made available in this release, making the nanodac™ suitable for applications in Food & Beverage or CIP/SIP.

Server mode or EtherNET/IP Client

As an option the nanodac™ recorder/controller can be easily integrated with an existing instrument network, and act as local data historian. When enabled, EtherNet/IP allows the nanodac™ to act as either a Server or a Client, and (via virtual channels) provides data recording for up to 30 process parameters.

EtherNet/IP provides two user pages: the first is a diagnostics page that can be used during initial setup and commissioning, to test the connection, between the Client and or Server. The second is an overview of all the process parameters (data points) being addressed via the communications.

Data Recording and Acquisition

The nanodac™ recording functionality utilizes the secure strategies and UHH format developed by Eurotherm through years of recording expertise. As well as multiple real-time views and historical review on the product, multiple data archiving strategies are provided using the 50MB onboard Flash memory, removable USB and data transfer via FTP to a specified server.

The four universal input channels provide high accuracy (suitable for use in Nadcap applications) and 125ms parallel sampling. An additional 30 virtual channels can be utilized to provide math, counter, slave communications and totalizer functionality within the instrument.

3 x Isolated DC Outputs (DDD)

This release provides support for Isolated DC Outputs in option slots OP1, OP2 and OP3. Please refer to the Installation sheet or User Guide for wiring instructions. The Eurotherm nanodac™ provides the ultimate in graphical recording combined with PID control and setpoint programs.

The compact ¼ DIN panel mount unit offers four high accuracy universal inputs for data recording and PID control. It is a secure data recording device with accurate control and is enhanced by a full color, ¼ VGA display which brings a crystal clear operator interface to even the smallest of machines.

YouTube video https://www.youtube.com/watch?v=ufDyyx9P7N4

PID Control Loops

The nanodac™ instrument can also provide two independent control loops (optional). This control functionality utilizes the advanced Eurotherm PID algorithm providing high performance and reliability to your process. It has one of the best auto-tunes facilities available along with overshoot inhibition (cutbacks); compensation for power fluctuations using power feedforward; linear, fan, oil and water cooling.

In the Heat Treatment processes set-points often need to vary control process over a set period. So this is achieved by using a set-point program.

The nanodac™ offers an optional Dual Programmer supporting up to 100 programs locally, each program supporting 25 segments.

The nanodac™ also provides remote access to a further 100 programs that can be easily retrieved via FTP or USB memory stick.

Their display is crystal clear

The 3.5” TFT display offers incredibly clear visualization of process parameters with a wide selection of configurable views to best suit the application. You gave the following views: Numeric; Horizontal and vertical trends; Horizontal and vertical bar graphs; Alarm panel, Alarm status, and control loops. User wiring from the front of the product, provides for detailed configuration without the need to connect to a PC.

Wash down Front

An optional IP66 rated Wash-down bezel has been made available in this release, making the nanodac™ suitable for applications in Food & Beverage or CIP/SIP.

Server mode or EtherNET/IP Client

As an option the nanodac™ recorder/controller can be easily integrated with an existing instrument network, and act as local data historian. When enabled, EtherNet/IP allows the nanodac™ to act as either a Server or a Client, and (via virtual channels) provides data recording for up to 30 process parameters.

EtherNet/IP provides two user pages: the first is a diagnostics page that can be used during initial setup and commissioning, to test the connection, between the Client and or Server. The second is an overview of all the process parameters (data points) being addressed via the communications.

Data Recording and Acquisition

The nanodac™ recording functionality utilizes the secure strategies and UHH format developed by Eurotherm through years of recording expertise. As well as multiple real-time views and historical review on the product, multiple data archiving strategies are provided using the 50MB onboard Flash memory, removable USB and data transfer via FTP to a specified server.

The four universal input channels provide high accuracy (suitable for use in Nadcap applications) and 125ms parallel sampling. An additional 30 virtual channels can be utilized to provide math, counter, slave communications and totalizer functionality within the instrument.

3 x Isolated DC Outputs (DDD)

This release provides support for Isolated DC Outputs in option slots OP1, OP2 and OP3. Please refer to the Installation sheet or User Guide for wiring instructions.

Eurotherm Mini 8 Controller

Friday, February 17, 2017 6:41:00 AM America/New_York

"The Mini8 controller is an ideal partner to a programmable logic controller. Able to multi-drop on either Serial, Fieldbus or Ethernet communications. It offers a cost-effective alternative to performing analogue measurement or loop control in a PLC." The Mini8 Controller, a very competitive and compact data acquisition device, offers high performance control usually only found in Eurotherm panel mount PID controllers.

Its modular design enables its I/O and feature set to be selected to meet a wide range of applications from simple to complex.

The ideal partner to a programmable logic controller (PLC) is the Mini8 controller. It can multi-drop on either serial, Ethernet or Fieldbus communications and it offers a real, cost-effective alternative to performing loop control or analog measurement in a PLC.

By implementing these functions in the Mini8 controller hardware cost is reduced, relieving the PLC of the burden of performing analog functions - often allowing a lower specification processor to be used.

The feature set of the Mini8 controller includes graphical wiring, high performance PID control, and set-point programming functions together with logic, math and timing function blocks.

When used in a data acquisition installation the high density analog I/O can be combined with paperless graphic recorder products, like the Nanodac to provide unsurpassed local and network access to your process.