You have no items in your shopping cart.

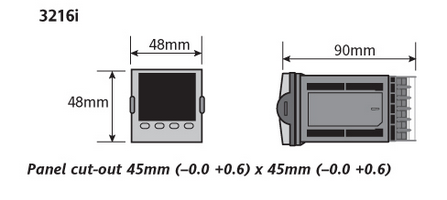

Eurotherm 3216i

Thursday, January 12, 2017 1:34:00 AM America/New_York

The Eurotherm 3216i indicators offer accurate indication of temperature and process measurements. Process interlocks, including overtemperature furnace limits, are implemented using relay output channels.

Industrial environments can do with instruments with simple usage. The same is available with Eurotherm 3216i and other indicators in this range.

Whether it concerns the indication of the breach of set limits or the protection of your process, you can use the 'Quick Start' code configure all the functions as you need them. When you need to implement process interconnections like over temperature furnace limits, you can use the provided relay output channels.

Uses:

Plastics - extrusion melt pressure

Level/pressure/flow

Weighing platform

Heat treatment - furnace over temperature

Temperature & process indication

Process protection

These Products Are Now Obsolete!

Thursday, January 5, 2017 1:31:00 AM America/New_York

Below are some of the Instruments or Controls that we can repair or refurbish. Need your current product repaired? Allow us to help you with your Eurotherm Obsoleted Instruments by providing replacements, refurbished units or by repairing your instrument.

- HEATSK-DIN-1.0

- I.O.-JUMPER-010

- I.O.-MARKER-011

- IO-IAC/+RO/280

- IO-IDC/+RO/28

- RSAA-660/50/10

- RVA3-6V75T/H

- SVAA-3V10

- SVDA-3V10

- SVDA-3V25

- SVDA-3V75

Efit SCR Power Controller

Wednesday, December 28, 2016 1:30:00 AM America/New_York

The Eurotherm EFit power controller is easy to commission and integrate. It is cost effective, but don’t provide any compromise in the control of resistive and infrared heating elements.

Cost effective and exceptional process performance

EFit is compliant with international standards of immunity, quality, and emissions, and can be used for all heating applications. The unit delivers precise control even in the most extreme industrial conditions, such as limited cabinet space.

Perfect for simple heating applications

Heat treatment and other such industrial processes need accurate temperatures to comply with regulations. However, this isn’t possible to achieve in a large industrial plant where fluctuations in voltage is a common phenomenon. If we consider resistive heaters, 20% variation in the power to the load can be caused with a variation of 10% in the supply voltage. This can cause unwanted temperature fluctuations. The EFit power control unit continues to deliver a uniform flow of power supply, even when there are voltage fluctuations. This will result in a continuous and reliable heating process that delivers products that comply with heat treatment standards.

Easy Installation

- Minimal connection — pre-wired plug in connectors

- Nothing to fix — just clip onto DIN rail

- Nothing to configure — plug and play

Control precisely

- Eliminate voltage fluctuations

- Achieve tight tolerances

- Optimize energy use

Improve processes

- Minimise downtime

- Maximise throughput

- Reduce cost of ownership

Tuning Eurotherm 2208e 1/8 DIN Controller

Wednesday, December 21, 2016 1:25:00 AM America/New_York

The method for automatic tuning automatically determines the value of the parameters listed in table 4-1 in the image above. The 2208e and 2204e uses a “one-shot” tuner in which works by switching the output on and off to induce an oscillation in the measured value. From the amplitude and period of the oscillation, it calculates the tuning parameter values.

If the tuning process cannot tolerate full heating or cooling being applied, then the level of heating or cooling can be restricted by setting the heating and cooling power limits in the Output list. However, the measured value must oscillate to some degree for the tuner to be able to calculate values.

A one-shot Tune can be performed at any time but normally, it is performed only once during the initial commissioning of the process. However, if the process under control subsequently becomes unstable (because its characteristics have changed), you can re-tune again for the new conditions.

It is best to start tuning with the process at ambient temperature. This allows the tuner to calculate more accurately the low cutback and high cutback values that restrict the amount of overshoot or undershoot.

Eurotherm 1/8 DIN 2108i Horizontal Mount Indicator and Alarm unit

Wednesday, December 14, 2016 1:16:52 AM America/New_York

The Eurotherm 2108i horizontal mount indicator and alarm unit provides accurate measurement and display of temperature and other processing variables in a standard 1/8 DIN panel format. The two alarm relay outputs are provided for an operator alert and process protection.

A universal input allows selection of nine internally stored thermocouple types. Other input linearization may be factory downloaded. Linear, process inputs are scalable to the desired range. Keylock and passwords prevent unauthorized access to configuration and alarm settings.

A large, red, or green LED display gives good visibility in low and high ambient lighting.

New alarms can be acknowledged and old alarms reset by a front panel button or an external contact closure input.

Three internal alarm setpoints are provided. They are configurable as high, or low, or rate of change alarms. Any combination of these three internal alarms can activate the two relay outputs. Latching or non-latching operation can be selected and alarm delays can be applied. A special mode known as “alarm blocking” is available. In this mode, after power on, the process value must first enter a good state before the alarm becomes active. This is particularly useful for low alarms which can be “blocked” while the process is warming-up.

Calibration accuracy is preserved with a self-correcting input circuit, while a User Calibration facility allows offsets to be applied to compensate for sensor and other system errors.

Eurotherm 3504 1/4 DIN Advanced Temperature Controller/Programmer

Wednesday, December 7, 2016 1:15:59 AM America/New_York

The 3504 controller is supplied in the standard ¼ DIN size (96 x 96mm front panel). The 3504 Controller contains up to six plug-in hardware modules; the 3508 Controller has up to three. Moreover, digital communications modules can be fitted in two positions.

These modules provide an interface to a wide range of plant devices and those fitted to it are identified by an ordering code printed on a label to the side of the instrument. This code defines the basic functionality of the instrument which may be:

- Controller only

- Programmer and controller

- Control type – Standard PID, valve positioner

- Digital communications type

- Options

General Eurotherm Product Obsolescence Procedure

Monday, November 21, 2016 2:32:00 AM America/New_York

During the life of the product, the Service and Repair activity monitor the level of repairs and use of spares.

As a minimum this activity must start no later than when the product is moved from 'Current' to 'Available' classification.

This information is used to help predict the spares stock holding requirements.

The review and definition of product status is carried out as required.

Purchasing, Manufacturing, Service Centre and Customer Support communicate, to the Portfolio Manager, any on-going issues that affect the ability of Eurotherm to continue the manufacture and supply of any product currently in the 'available' category, and during the 'Lifetime’ category to maintain Service Support. In such an instance a series of additional reviews are convened to monitor the situation and decide upon any extraordinary actions necessary. This may result in the premature entry of an instrument into an obsolescence category.

Basic Obsolescence Timing:

Progression through each phase of obsolescence requires acceptance of the plan by Marketing Director, Sales Director, R&D Director and Portfolio Manager.

Current / Preferred - ‘Level 1’ - Under Review'

Notification of Level 1 status is distributed to UK Sales and Service and Group Companies.

There is no feature development of products unless it affects safety or is to rectify field failures.

Alternative product offerings are identified. There may be a number of alternatives, depending upon the capabilities of the alternatives available. Definition of alternatives should include all information required to install the replacement instrument in place of the original. This includes cross-reference wiring information from one instrument to the other and operating instructions.

Availability - ‘Level 2’ – No longer available but may be by Special Order Only: The following products are in this category: 7200A, 7300A Full, 7300A Light , Continental Solid State Relays & IO Modules Special orders & repairs only

Some, but not all, replacements are scheduled for December 2016

Notification of Level 2 status is distributed to UK Sales and Service and Group Companies.

Lists of all known users, during the last two years, of the product to be provided to the Sales Engineers, Group Companies and direct to 'Third Party' operations as appropriate, together with personalized copies of a letter detailing status of the product in question and the possible alternatives.

In the UK, after three months all customers not yet contacted by the Sales Engineer to be contacted directly from Worthing England with a personalized letter detailing status of the product in question and defining recommended alternatives.

Purchasing need to be informed and demand (forecast) amended. Any last time buy requirements to be collated by UK Service center.

Apart from supporting documentation in the document library, all product promotional material is removed from the website.

Mature and Lifetime Care – ‘Level 3’ No Longer Available.' The following products are in this category:

7100A Light, 7100S, 7200S, 7300S, TE10S, TE200S, TE200A, TC2000 repairs only

Replacements scheduled for December 2016

Continue to promote alternative replacement products - include a notice in each repair returned.

Product Availability: None

Spares Availability: Limited for Service activities only.

Product should be removed from Sales Order Processing System and assemblies made obsolete.

Obsolete - ‘Level 4’ - Beyond Economical Repair

Continue to promote obsolescence status of the product and offer advantages of replacement with the alternatives available. Support is very limited, affected by spares stocks and replacement parts availability.

Eurotherm 2604 Master Communications

Monday, November 14, 2016 5:08:00 AM America/New_York

Software version 5 and above of the 2604 controller supports Master Communications. The objective of the master comms is to allow the 2604 to communicate with any instrument using ModBus interface as a master device, that is, without the need for a supervisory PC. This allows the 2604 to link through digital communications with other products to create a small system solution.

There are two methods of communication

1. Broadcast Communications

2. Direct Read/Write

Broadcast Communications

The 2604 master can be connected to up to 32 slaves. The master sends a unit address of 0 followed by the address of the parameter which is to be sent. A typical example might be a multi zone oven where the setpoint of each zone is required to follow, with digital accuracy, the setpoint of a master.

Direct read/write

The 2604 master can be connected to up to eight slaves. Each slave has its own unit address. The master can send data to each slave by sending a unit address followed by the parameter address. It can also request data from a slave. This data may be displayed on the 2604 or used as part of a 2604 control strategy.

Eurotherm 2416 TUNING

Monday, November 7, 2016 4:32:00 AM America/New_York

Two automatic tuning procedures are provided in the 2416:

• A one-shot tuner which automatically sets up the initial values of the parameters listed in Table 4-1 below.

• Adaptive tuning which continuously monitors the error from setpoint and modifies the PID values if necessary.

One-shot Tuning:

The ‘one-shot’ tuner works by switching the output on and off to induce an oscillation in the measured value. From the amplitude and period of the oscillation, it calculates the tuning parameter values. If the process cannot tolerate full heating or cooling being applied during tuning, then the level of heating or cooling can be restricted by setting the heating and cooling power limits in the ‘oP’ list.

However, the measured value must oscillate to some degree for the tuner to be able to calculate values. A One-shot Tune can be performed at any time, but normally it is performed only once during the initial commissioning of the process. However, if the process under control subsequently becomes unstable (because its characteristics have changed), you can re-tune again for the new conditions.

It is best to start tuning with the process at ambient temperature. This allows the tuner to calculate more accurately the low cutback and high cutback values which restrict the amount of overshoot, or undershoot.

How to tune

1. Set the setpoint to the value at which you will normally operate the process.

2. In the ‘Atun’ list, select ‘tunE’ and set it to ‘on’.

3. Press the Page and Scroll buttons together to return to the Home display. The display will flash ‘tunE’ to indicate that tuning is in progress.

4. The controller induces an oscillation in the temperature by first turning the heating on, and then off. The first cycle is not complete until the measured value has reached the required setpoint.

5. After two cycles of oscillation the tuning is completed and the tuner switches itself off.

6. The controller then calculates the tuning parameters listed in Table 4-1 above, and resumes normal control action. If you want ‘Proportional only’, ‘PD’, or ‘PI’ control, you should set the ‘ti’ or ‘td’ parameters to OFF before commencing the tuning cycle. The tuner will leave them off and will not calculate a value for them.

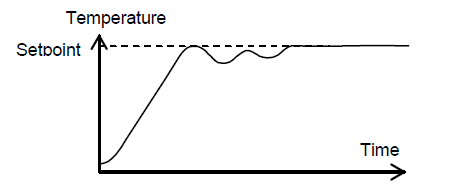

Typical automatic tuning cycle

Calculation of the cutback values

Low cutback and High cutback are values that restrict the amount of overshoot or undershoot that occurs during large step changes in temperature (for example, under start-up conditions). If either low cutback, or high cutback, is set to ‘Auto’ the values are fixed at three times the proportional band, and are not changed during automatic tuning.

Adaptive tune

Adaptive tuning is a background algorithm, which continuously monitors the error from setpoint and analyses the control response during process disturbances. If the algorithm recognizes an oscillatory, or under-damped, response it recalculates the Pb, ti and td values. Adaptive tune is triggered whenever the error from setpoint exceeds a trigger level. This trigger level is set in the parameter ‘drA.t’, which is found in the Autotune list. The value is in display units. It is automatically set by the controller, but can also be manually re-adjusted. Adaptive tune should be used with:

1. Processes whose characteristics change as a result of changes in the load, or setpoint.

2. Processes that cannot tolerate the oscillation induced by a One-shot tune.

Adaptive tune should not be used:

1. Where the process is subjected to regular external disturbances that could mislead the adaptive tuner.

2. For highly interactive multi-loop applications.

However, moderately interactive loops, such as multi-zone extruders, should not give a problem.

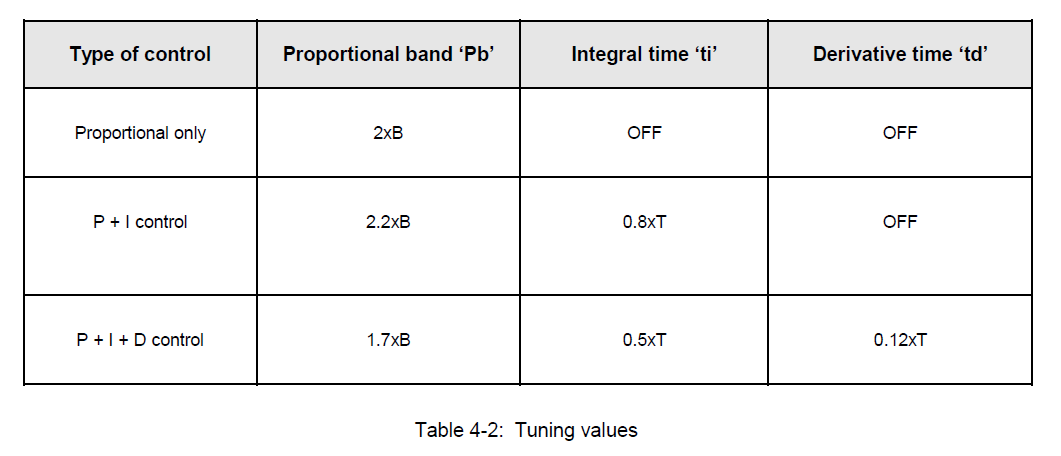

MANUAL TUNING

If for any reason automatic tuning gives unsatisfactory results, you can tune the controller manually. There are a number of standard methods for manual tuning. The one described here is the Ziegler-Nichols method.

With the process at its normal running temperature:

1. Set the Integral Time ‘ti’ and the Derivative Time ‘td’ to OFF.

2. Set High Cutback and Low Cutback, ‘Hcb’ and ‘Lcb’, to ‘Auto’.

3. Ignore the fact that the temperature may not settle precisely at the setpoint.

4. If the temperature is stable, reduce the proportional band ‘Pb’ so that the temperature just starts to oscillate. If the temperature is already oscillating, increase the proportional band until it just stops oscillating. Allow enough time between each adjustment for the loop to stabilize. Make a note of the proportional band value ‘B’ and the period of oscillation ‘T’.

5. Set the Pb, tiand td parameter values according to the calculations given in

Eurotherm 3508 1/8 DIN Process Controllers

Monday, October 24, 2016 9:08:00 AM America/New_York

The 3508 controller is supplied in the standard 1/8 DIN size (48 x 96mm front panel).

It is intended for permanent installation, for indoor use only, in an electrical panel, which encloses the rear housing, terminals and wiring on the back.

The functionality of controller depends on the features which have been ordered, see order code Section 1.2 below. Examples are:-

Programmer. A programmer varies the rate of change of setpoint allowing a profile to be set up.

Plug in modules. These provide customized input/output to plant devices.

The functionality of the controller also depends on how it has been configured. When it is first supplied the controller will enter a Quick Configuration mode which allows a basic set of features to be set up operation ‘out of the box’..png)

Further detailed configuration may be achieved either by using iTools configuration package or entering deeper levels of access. An Engineering Handbook, Part no. HA027988, provides a detailed description together with an explanation of terminology and may be ordered or downloaded from http://eurothermonline.com/instrumental-manuals/3500-series-manuals-and-brochures/

Section 1.2 Ordering Codes

The controller may have been ordered in accordance with the hardware code listed below. Additionally, it may have been ordered by quoting the ‘Quick Code’ listed in section 1.3. If ordered to the quick code the controller will be configured in the factory. If it is not ordered using the quick code then it will be necessary to configure the controller when it is first switched on.

Section 1.3 Quick Codes Use the tables below to determine your quick start code

To get assistance with ordering code, please call our office 800-849-5655, or use this form to contact us.