You have no items in your shopping cart.

Eurotherm NANODAC

Friday, February 10, 2017 6:27:00 AM America/New_York

The Eurotherm nanodac™ provides the ultimate in graphical recording combined with PID control and setpoint programs.

The compact ¼ DIN panel mount unit offers four high accuracy universal inputs for data recording and PID control. It is a secure data recording device with accurate control and is enhanced by a full color, ¼ VGA display which brings a crystal clear operator interface to even the smallest of machines.

YouTube video https://www.youtube.com/watch?v=ufDyyx9P7N4

PID Control Loops

The nanodac™ instrument can also provide two independent control loops (optional). This control functionality utilizes the advanced Eurotherm PID algorithm providing high performance and reliability to your process. It has one of the best auto-tunes facilities available along with overshoot inhibition (cutbacks); compensation for power fluctuations using power feedforward; linear, fan, oil and water cooling.

In the Heat Treatment processes set-points often need to vary control process over a set period of time. So this is achieved by using a set-point program.

The nanodac™ offers an optional Dual Programmer supporting up to 100 programs locally, each program supporting 25 segments.

The nanodac™ also provides remote access to a further 100 programs that can be easily retrieved via FTP or USB memory stick.

Ther display is crystal clear

The 3.5” TFT display offers incredibly clear visualization of process parameters with a wide selection of configurable views to best suit the application. You gave the following views: Numeric; Horizontal and vertical trends; Horizontal and vertical bar graphs; Alarm panel, Alarm status, and control loops. User wiring from the front of the product, provides for detailed configuration without the need to connect to a PC.

Wash down Front

An optional IP66 rated Wash-down bezel has been made available in this release, making the nanodac™ suitable for applications in Food & Beverage or CIP/SIP.

Server mode or EtherNET/IP Client

As an option the nanodac™ recorder/controller can be easily integrated with an existing instrument network, and act as local data historian. When enabled, EtherNet/IP allows the nanodac™ to act as either a Server or a Client, and (via virtual channels) provides data recording for up to 30 process parameters.

EtherNet/IP provides two user pages: the first is a diagnostics page that can be used during initial setup and commissioning, to test the connection, between the Client and or Server. The second is an overview of all the process parameters (data points) being addressed via the communications.

Data Recording and Acquisition

The nanodac™ recording functionality utilizes the secure strategies and UHH format developed by Eurotherm through years of recording expertise. As well as multiple real-time views and historical review on the product, multiple data archiving strategies are provided using the 50MB onboard Flash memory, removable USB and data transfer via FTP to a specified server.

The four universal input channels provide high accuracy (suitable for use in Nadcap applications) and 125ms parallel sampling. An additional 30 virtual channels can be utilized to provide math, counter, slave communications and totalizer functionality within the instrument.

3 x Isolated DC Outputs (DDD)

This release provides support for Isolated DC Outputs in option slots OP1, OP2 and OP3. Please refer to the Installation sheet or User Guide for wiring instructions. The Eurotherm nanodac™ provides the ultimate in graphical recording combined with PID control and setpoint programs.

The compact ¼ DIN panel mount unit offers four high accuracy universal inputs for data recording and PID control. It is a secure data recording device with accurate control and is enhanced by a full color, ¼ VGA display which brings a crystal clear operator interface to even the smallest of machines.

YouTube video https://www.youtube.com/watch?v=ufDyyx9P7N4

PID Control Loops

The nanodac™ instrument can also provide two independent control loops (optional). This control functionality utilizes the advanced Eurotherm PID algorithm providing high performance and reliability to your process. It has one of the best auto-tunes facilities available along with overshoot inhibition (cutbacks); compensation for power fluctuations using power feedforward; linear, fan, oil and water cooling.

In the Heat Treatment processes set-points often need to vary control process over a set period. So this is achieved by using a set-point program.

The nanodac™ offers an optional Dual Programmer supporting up to 100 programs locally, each program supporting 25 segments.

The nanodac™ also provides remote access to a further 100 programs that can be easily retrieved via FTP or USB memory stick.

Their display is crystal clear

The 3.5” TFT display offers incredibly clear visualization of process parameters with a wide selection of configurable views to best suit the application. You gave the following views: Numeric; Horizontal and vertical trends; Horizontal and vertical bar graphs; Alarm panel, Alarm status, and control loops. User wiring from the front of the product, provides for detailed configuration without the need to connect to a PC.

Wash down Front

An optional IP66 rated Wash-down bezel has been made available in this release, making the nanodac™ suitable for applications in Food & Beverage or CIP/SIP.

Server mode or EtherNET/IP Client

As an option the nanodac™ recorder/controller can be easily integrated with an existing instrument network, and act as local data historian. When enabled, EtherNet/IP allows the nanodac™ to act as either a Server or a Client, and (via virtual channels) provides data recording for up to 30 process parameters.

EtherNet/IP provides two user pages: the first is a diagnostics page that can be used during initial setup and commissioning, to test the connection, between the Client and or Server. The second is an overview of all the process parameters (data points) being addressed via the communications.

Data Recording and Acquisition

The nanodac™ recording functionality utilizes the secure strategies and UHH format developed by Eurotherm through years of recording expertise. As well as multiple real-time views and historical review on the product, multiple data archiving strategies are provided using the 50MB onboard Flash memory, removable USB and data transfer via FTP to a specified server.

The four universal input channels provide high accuracy (suitable for use in Nadcap applications) and 125ms parallel sampling. An additional 30 virtual channels can be utilized to provide math, counter, slave communications and totalizer functionality within the instrument.

3 x Isolated DC Outputs (DDD)

This release provides support for Isolated DC Outputs in option slots OP1, OP2 and OP3. Please refer to the Installation sheet or User Guide for wiring instructions.

Eurotherm Mini 8 Controller

Friday, February 17, 2017 6:41:00 AM America/New_York

"The Mini8 controller is an ideal partner to a programmable logic controller. Able to multi-drop on either Serial, Fieldbus or Ethernet communications. It offers a cost-effective alternative to performing analogue measurement or loop control in a PLC." The Mini8 Controller, a very competitive and compact data acquisition device, offers high performance control usually only found in Eurotherm panel mount PID controllers.

Its modular design enables its I/O and feature set to be selected to meet a wide range of applications from simple to complex.

The ideal partner to a programmable logic controller (PLC) is the Mini8 controller. It can multi-drop on either serial, Ethernet or Fieldbus communications and it offers a real, cost-effective alternative to performing loop control or analog measurement in a PLC.

By implementing these functions in the Mini8 controller hardware cost is reduced, relieving the PLC of the burden of performing analog functions - often allowing a lower specification processor to be used.

The feature set of the Mini8 controller includes graphical wiring, high performance PID control, and set-point programming functions together with logic, math and timing function blocks.

When used in a data acquisition installation the high density analog I/O can be combined with paperless graphic recorder products, like the Nanodac to provide unsurpassed local and network access to your process.

Eurotherm 3058

Friday, February 24, 2017 6:47:00 AM America/New_York

The 3508 large 5-digit display provides a clear and unambiguous indication of the process value. A four-line message centre provides custom or standard views of important information to the user while vertical and horizontal bargraphs provide at a glance visual indication of the process.

The Eurotherm 3508 is a 1/8 DIN process controller belonging to the most advanced range of products in this category. It offers precision control of a range of process variables, such as temperature. It has advanced features that offer great flexibility.

For configuring basic functions, including control options, alarms, sensor type, and measurement range a 'Quick Start' process can be used. The unit combines flexibility with ease of use. For configuring advanced features, users can use a PC based tool that allows them to select functions from a library.

Ideal for:

Semi-conductors

Process applications

Reactors and Fermenters

Autoclaves

Environmental chambers

Melt pressure

Heat Treatment

Features:

Precision PV input

Math/logic/timers

Modbus RTU

Recipes

50 Programs

Carbon potential

Ethernet Modbus TCP

2 PID loops

Custom user interface

Profibus DPDeviceNet network

Two New Additional Products

Friday, March 3, 2017 8:12:34 AM America/New_York

The “EPACK-2PH” and “EPACK-3PH” has been added to the Power Control section of our Eurothermonline store. For those who wish to upgrade their furnaces or heating equipment from analog to digital SCRs, the EPack is the perfect solution for OEMs and End Users.

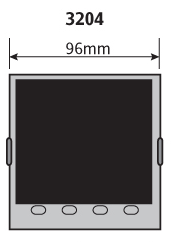

Eurotherm 3204 Heat Current Monitoring

Friday, March 10, 2017 8:49:14 AM America/New_York

A current transformer input provides display of the heater current and a health check on the load. Partial load failure, heater open circuit and SSR faults are detected and displayed as scrolling alarm messages as well as providing an alarm output. A front panel ammeter displays the heater current on the 3204.

Eurotherm 3216

Friday, March 17, 2017 8:26:00 AM America/New_York

The Eurotherm 3216 is Quick and easy commissioning - no need for expert knowledge. Clear information of process with scrolling, custom messages. Custom alarm messages for easy understanding. Recipe selection from operator interface. Internal timer and set point programming. Instant indication of heater faults with integral ammeter. Remote set point - solution for multi-zone applications.

The Eurotherm 3216 controller comes with many advanced features that are not available that are commonly available in similar controllers. It provides precision control of process variables like temperature.

Eurotherm 2704 Status Messages

Friday, March 24, 2017 8:33:00 AM America/New_York

Here’s an outline that describes the status messages for the Eurotherm 2704 Multi Loop Controller. These messages appear on the display to show the status of the controller.

The Eurotherm 3508

Friday, April 7, 2017 4:23:32 AM America/New_York

The 3508 large 5-digit display provides a clear and unambiguous indication of the process value. A four-line message centre provides custom or standard views of important information to the user while vertical and horizontal bargraphs provide at a glance visual indication of the process.

The Eurotherm 3508 is a 1/8 DIN process controller belonging to the most advanced range of products in this category. It offers precision control of a range of process variables, such as temperature. It has advanced features that offer great flexibility.

For configuring basic functions, including control options, alarms, sensor type, and measurement range a 'Quick Start' process can be used. The unit combines flexibility with ease of use. For configuring advanced features, users can use a PC based tool that allows them to select functions from a library.

Ideal for:

Semi-conductors

Process applications

Reactors and Fermenters

Autoclaves

Environmental chambers

Melt pressure

Heat Treatment

Features:

Precision PV input

Math/logic/timers

Modbus RTU

Recipes

50 Programs

Carbon potential

Ethernet Modbus TCP

2 PID loops

Custom user interface

Profibus DPDeviceNet network

Eurotherm 2132i

Friday, April 14, 2017 3:34:00 AM America/New_York

A universal input enables selection of nine internally stored thermocouple types and the PT100 resistance thermometer. Linear inputs can be scaled to the desired display range. Two relay outputs are configurable for alarms. Three internal alarm setpoints are provided- configurable as high, low or deviation. Alarms can be 'blocked' on start-up to prevent unnecessary operator alerts.

2100 Series Controller

The compact Eurotherm, 1/32 DIN panel size, 2132 temperature controller uses advanced PID algorithms to give stable temperature control. Specialist knowledge or training is not needed to optimize the control performance, because Self-tuning is included.

- Simple operation

- Three internal alarms

- Up to two relay outputs

- One logic input or output

- Reliable performance and accuracy

- Internal timer - a 5 mode timer suitable for simple time based profiling applications

- Universal input - 9 thermocouple types, PT100, DC linear and a downloadable custom curve

Universal input/two outputs

Linear inputs can be scaled to the desired display range. A universal input enables selection of nine internally stored thermocouple types and the PT100 resistance thermometer. Other input linearizations may be factory downloaded. Two outputs are configurable for heating, cooling or alarms.

Operator interface

The operator interface can be customized to present only those parameters that an operator needs to see and adjust, while other parameters are locked away under password protection.

Internal alarm set points

Alarms can be 'blocked' on start-up to prevent unnecessary operator alerts. Three internal alarm set points are provided - configurable as high, low or deviation alarms.

Heater failure can be detected using PDSIO when the controller is used with a TE10S Solid State Relay - this negates the need to use extra components such as current transformers.

Internal timer

A five-mode timer is provided for simple, time-based profiling applications. Ideal for:

- Trace heating

- Sterilizers

- Chillers

- Plastics - extrusion

- Heat treatment -small ovens

- Heat sealing

Features:

- Customized operator interface

- Three internal alarm set points

- Universal input selection

- Two configurable outputs

- Heater failure detection

- Tactile buttons

The Eurotherm 2408i

Friday, April 21, 2017 4:15:00 AM America/New_York

The 2408i provides accurate measurement with flexible functions. Accurate, stable measurement of temperature, pressure, level, flow and other process variables are provided by the 2408i. An optional second process value input allows the average, difference, minimum or maximum of two values to be displayed. Large, bright, red or green displays ensure good visibility in high and low ambient lighting.

The 1/8 DIN Eurotherm 2408i makes process and temperature measurements easy by providing alarming and indication functions. Relay outputs are used to implement process interlocks, such as over temperature furnace limits.

- Extrusion melt pressure indication and alarming

- Modular construction offering increased I/O flexibility

- Second process input provide additional alarming strategies

- Furnace over temperature limits

- Large 5 digit display providing excellent visibility

- Fieldbus communications providing system integration

The unit helps users select from the 9 available sensor types that are store internally, with its universal input capability. Users can scale linear input as desired. For more input linearizations, users can use iTools for download. Indication of non-linear signals is achieved using the 15 point linearization.

The process value is clearly displayed on the green or red 5 inch display. For displaying and alarming on the maximum, minimum, average, and difference of two values, the second process input can be used.

The unit provides great flexibility by allowing the attachment of up to 3 I/O modules from the available 9. Conventional analog retransmission or digital communications can be used to achieve system integration.

Applications include:

- Plastics processing - Extrusion melt pressure

- Heat treatment - Furnace over temperature

- Temperature & process indication

- Process protection

- Weighing platforms

Features:

- Universal input

- Profibus DP

- Strain gauge input

- Serial Modbus™ comms

- Red or green display

- Process variable retransmission

- Devicenet