You have no items in your shopping cart.

Supervisory and Control Systems for Forming Windscreens using Eurotherm ePower

Monday, October 17, 2016 8:39:00 AM America/New_York

With the rapidly changing glass panels industry for cars, the complexity of shape and integration of sensors has been critical. As more demands for more stringent tolerances and the introduction of more complex forms and shapes, the automobile production process for glass panels has become extremely complex.

For example in a Tunnel Furnace where hundreds of sub zones, requiring precise and complex temperature control, running multiple recipes to allow maximum production, flexibility is a necessity. Resistive elements as well as medium wave infrared heaters have to be controlled to very tight parameters while maximizing energy efficiency.

Around the world, Eurotherm temperature control, power control and supervisory systems for windscreen forming are in operation. They provide:

- Accurate open or closed loop power control

- Accurate multi-zone temperature control

- Power control set point transfer and monitoring by digital communication, reducing the I/O requirements of the control system

- Feed through control

- Advanced single cycling for infra-red elements, eliminating DC components

- Track and Trace capability

In power glass applications, Eurotherm has always been present and successful:

- Bottle manufacturing: boosting, feeder heating

- Windscreen forming

- Flat glass: roof heating, annealing

- Glass wire manufacturing: boosting, feeder heating, bushing

The principle of windscreen forming is that the flat windscreen is going through a tunnel furnace on a very precise form. There is one type of form per type of windscreen. When at the right temperature, assisted by gravity the soft glass will take accurately to the form.

The pre-heating zone is the first part of the furnace where the temperature accurately controlled. The second part is the forming zone with a precise electrical power control. Heating elements are metallic resistors, medium wave infra-red, with a low temperature coefficient. Heat transfer to the windscreen is a combination of infra-red emission and air heating.

The quality and precision of the windscreen banding is given by the accuracy of forming zone power control and the accuracy of the pre-heating zone temperature controls.

On these furnaces, the number of zones can be very high, 100 to 300 zones. Present tendency is to increase the number of zones to improve precision of banding and to manufacture more complicated and various windscreen shapes. The total power of such furnaces can be several hundred kW to several MW.

Architecture of the installation

- The electrical control architecture of the installation is as follows:

- A PLC supervisory system is controlling the furnace: temperature in pre-heating, zone, power informing zone.

- Heating elements power control is made with multi-channel communicating power units, EPower Series for both forming and pre-heating zones.

- Firing mode: single cycle.

- Control mode: precise power U x I, very important for banding accuracy.

- Through communication link (Modbus or Profibus depending on type of PLC), all EPower parameters are available (read and write) on the supervisory system: load output, power set point, status word/alarms.

Millisecond set point transfer

On the furnace forming part, during process time each windscreen stays in a heating zone; its next working set point, for the next heating zone it will move into, is loaded in each EPower channel. When all the windscreens reach their next heating zone, a single command through the communication link will transfer in a few milliseconds all pre-loaded set points for each zone as an active set point.

Use this Eurotherm solution to your advantage

- Perfectly adapted for this application is the Thyristor firing mode: single cycle.

- Power control mode for a better process control

- Avoids peak power demands with Predictive Load Management (PLM).

- Reduce installation cost with multichannel EPower: floor space saving and smaller panels, lower cost per channel.

- Very good accuracy of EPower power control U x I: absolutely necessary to Communication

- Installation costs are reduced (wiring, cabinetry, etc.).

- Process control efficiency and quality are improved.

Checkout all our power controls at http://eurothermonline.com/power-controls.htmlhttp://eurothermonline.com/power-controls.html

Eurotherm Models 2404 And 2408 Are High Stability, Temperature Or Process Controllers With Self And Adaptive Tuning

Monday, October 10, 2016 7:02:00 AM America/New_York

They have a modular hardware construction which accepts up to three plug-in Input/Output modules and two interface modules to satisfy a wide range of control requirements. Two digital inputs and an optional alarm relay are included as part of the fixed hardware build. The instruments are available as:

- standard controllers - which include a basic 8-segment programmer Models 2408/CC and 2404/CC

- setpoint programming controllers: Models 2408/CP, P4, CM and 2404/CP, P4, CM

- motorized valve controllers - which include a basic 8-segment programmer Models 2408/VC and 2404/VC

- setpoint programming motorized valve controllers: Models 2408/VP, V4, VM and 2404/VP, V4, VM

Before proceeding, please read the Safety and EMC Information as follows:

This controller complies with the European Low Voltage Directive 2006/95/EC, by the application of the safety standard EN 61010. It is intended for industrial temperature and process control applications when it will meet the requirements of the European Directives on Safety and EMC. Use in other applications, or failure to observe the installation instructions of this handbook may impair the safety or EMC protection provided by the controller. It is the responsibility of the installer to ensure the safety and EMC of any particular installation.

The labels on the sides of the controller identify the ordering code, the serial number, and the wiring connections.

Understanding the Ordering Code

The 2408 and 2404 controllers have a modular hardware construction, which accepts up to three plug-in Input/Output modules and two communications modules to satisfy a wide range of control requirements. Two digital inputs and an optional alarm relay form part of the fixed hardware build. The ordering code is in two parts. The hardware coding and an optional configuration coding. The hardware coding specifies the basic build of the controller and the plug-in modules that are fitted

Eurotherm Nanodac used to Control the dosing level of a liquid or gas

Monday, October 3, 2016 8:45:00 AM America/New_York

Let’s describe how the nanodac can be used to control the dosing level of a liquid or gas using the Feedforward feature of the PID algorithm to achieve an output proportional to the flow rate of the fluid.

Data Recorder with PID Control

The nanodac recorder/controller provides combined recording and control in a single ¼ DIN package.

The Nanodac is ideal for use on any application requiring up to four real universal inputs. In addition, fourteen inputs can also be written to over communications effectively making an 18 channel data logger. It also contains 2 PID control loops, which can be configured to control temperature, pressure, level, and process variables such as flow, etc,.

Additionaly, the nanodac recorder provides powerful logging and secure archiving of the data. It can store information in either or a secure (UHH), or open CSV format, or a check summed format to protect data integrity.

Also available is live trending, a simple menu allows any selected portion of the recorder history to be archived, either to a ‘memory stick’ plugged into the USB port at the rear of the recorder (Local Archiving) or to a computer or server, by means of the FTP protocol (Remote Archiving). This archived data remains in the flash (50MB) memory of the instrument and can be reviewed directly on the instrument display.

Archive period between the last hour, last day, last week, last month, can be chosen. Also one can archive everything in the recorders history or archive all files created since or updated since the last archive.

The archive status is displayed on the nanodac recorder/controller, which shows when data is being transferred or is complete. The archive data includes actual values from real or communications channels (PV), Alarm Messages, and Operator Input Messages. All of this information is accurately dated and time stamped from the on-board real time clock.

Residual control (Dosing)

Dosing or residual control, as it is also known, is the nomenclature given to the technique for controlling the addition of a substance to a flowing liquid or gas. Typically a dosing system is designed so that the required dosing level can be achieved by maintaining the control signal as a proportion of the fluid flow rate. The residual (dosing) level is used by the control algorithm to trim the output signal by the required amount. Any industry that mixes substances into flowing fluids potentially has the requirement for this type of control. These include the water, distilling, brewing, concrete, china clay, paper and soft drink industries or any process requiring disinfection in cooling towers, drinking water, food and beverage, swimming pools and wastewater.

Dosing Control Example

The figure above shows the general arrangement of the dosing control system which in this example uses chlorine as the dosing additive. The main fluid flow is measured upstream from the dosing pump, while the chlorine level is measured downstream. The feed forward feature in the control loop is used to achieve an output proportional to the fluid flow rate. This means that the dosing rate immediately tracks any changes in the flow rate and so avoids under or over dosing.

The dosing concentration, measured downstream, can be used to provide closed loop PID control action to trim the feed forward output. When the flow rate varies so will the transport delay of the control loop. To compensate for this, the integral time of the controller should be increased as the fluid flow rate reduces. This is achieved by using the Gain Scheduling feature of the nanodac recorder/controller. Three sets of control parameters are available, the active set selected according to the flow rate.

In some cases the dosing level to be controlled is further downstream from the dosing pump. This maybe by as much as fifteen to thirty minutes at normal flow rates. In these cases, providing the dosing level can also be measured much closer to the pump then the second loop in the nanodac recorder/controller can be used in cascade. The master loop controls the dosing level at the point further downstream. Process feedforward can still be used to compensate for flow rate changes.

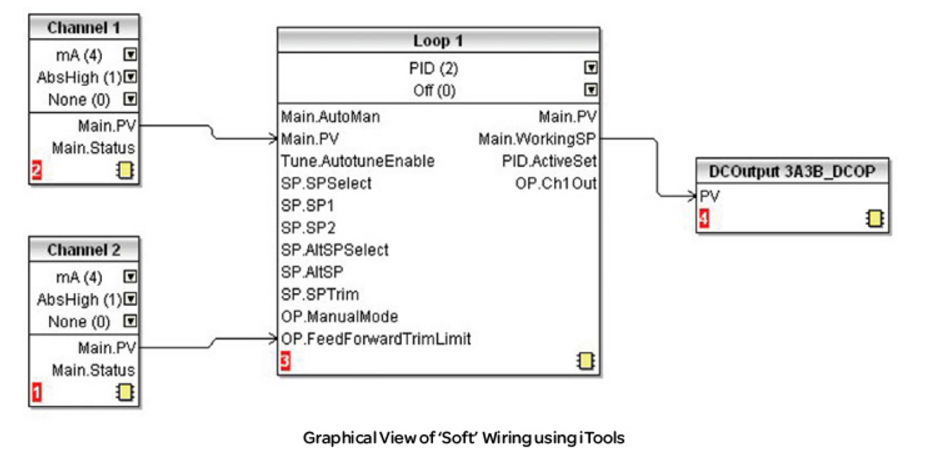

Internal ‘Soft’ Wiring

In the above example, dosing level is measured using channel 1 configured for 4-20mA input. It is connected to the main PV input of the control loop.

The flow rate is measured upstream using channel 2 configured for 4-20mA input, which is connected to the Feedforward input of the control loop.

The Control output is connected via Output Module 3. This is assumed to be 4-20mA in this example, but other outputs (such as on/off) may be used to match the type of pump in use.

Eurotherm 3216, 3208, 32h8 and 3204 Are Powerful And In Stock At Discounted Prices!

Thursday, September 15, 2016 9:14:00 AM America/New_York

The Eurotherm 3200 series of controllers are available in the following DIN sizes 1/16 3216, 1/8 3208, 1/8 horizontal 32h8 and 1/43204 DIN panel sizes.

The Eurotherm 2216e Is a Versatile, High Stability Temperature or Process Controller

Thursday, September 8, 2016 9:09:00 AM America/New_York

Obsolescence Stage for Select Eurotherm Power Products

Friday, September 2, 2016 9:58:00 AM America/New_York

|

7100L |

ESwitch |

|

|

Due to a short-notice, last-time-buy notification from our suppliers of some key components, it has become necessary for us to accelerate our obsolescence process for select products in our Power Product portfolio.

The following is a summary of the obsolescence stage for each of the affected products:

As of September, 30th 2016 orders for the following products will no longer be accepted (Level3 Obsolescence):

Product manufacture ceases.

Full Repair support available subject to component availability

|

Instrument |

Replacement |

|

7100L |

ESwitch (up to 50A |

|

7100S |

|

|

7200S |

EPack-2PH |

|

7300S |

Epack-3PH |

|

TE200S |

EPack-2PH |

|

TE200A |

EPack-2PH |

|

TC2000 |

Please feel free to call us 800-849-5655 or go on-line and complete the form for possible replacement as needed.

As of May, 31st 2017 orders for the following products will no longer be accepted (Level3 Obsolescence):

Note that these products will remain in Level 2 Obsolescence until approximately that date:

Range of available options and features becomes restricted

Product Availability may be restricted

Spares Availability: Restricted to Service activities only

|

Instrument |

Replacement |

|

7100A |

|

|

7100A |

EPack-2PH |

|

7200A |

EPack-3PH |

Please feel free to call us 800-849-5655 or go on-line and complete the form for possible replacement as needed.

New Product Note:

The EPack-2PH and -3PH series up to 125A are scheduled for first shipments in early next year with the order book expected to open before the end of the year.

These products will be similar in essence to the EPack 1phase already available now, with two and three phase versions. More information on these new products will be provided soon

Eurotherm 2132 Temperature Control For a Flexible Solution

Thursday, September 1, 2016 9:02:51 AM America/New_York

Eurotherm 2132 (1/32 DIN) Temperature Controllers provide flexible solutions.

The Eurotherm 2132 instruments use advanced PID algorithms to give stable ‘straight line’ temperature control. Self-tuning is included to optimize the control performance without the need for specialist knowledge or training.

Read MoreRecipe Function for 3000 Series Eurotherm Instruments like in the Model 3204

Thursday, August 18, 2016 1:09:00 AM America/New_York

The 3000 recipe function is unique one in many controllers of this class. Recipes can be stored under a user-defined name to recall a number of parameter settings. These settings may include operating variables or configuration parameters, providing a very powerful means of altering the setup of a controller in a single operation. Recipes may be recalled either from the HMI, over the communications link, or using digital inputs.

Heater Failure Detection in 3200 Series Eurotherm Controllers, like in the Model 3208

Thursday, August 11, 2016 1:08:08 AM America/New_York

A current transformer input in the 3200 measures the current switched through the load. The measurement is filtered so that the on current and off currents can be separated. From this, it is possible to diagnose several load faults including partial load failure, over current and an SSR fault. Typical applications include plastic extrusion, laboratory ovens and other applications where early indication of heater failure can save energy and rework costs.

Tempering with Eurotherm

Tuesday, July 26, 2016 3:44:00 AM America/New_York

Tempering is used to improve the hardness and elasticity of (steel or other metal) by reheating and then cooling it.

Eurotherm has supplied hundreds of its PID temperature controllers and single-phase power control units to customers for controlling heat treatment, tempering ovens and annealing used in the manufacture of disposable razor blades, and other precision metal products.

For the blade market, obtaining a good shave requires a blade with the finest edge, which explains why quality and production consistency are fundamental requirements.

The key to achieving these important goals depends partly on the precise control of temperature in the heat treatment, annealing and tempering furnaces. Eurotherm controllers are used in these applications, as well as the injection molding process for the razor body and in special-purpose printing machines.

By providing controls like the Eurotherm 32h8 and Epack-1 PH power controls production machines achieve very the high standard of temperature accuracy and uniformity demanded by the customer. As a result, their production facilities maintain a consistent high quality, which, in turn, reduces scrap and increases productivity.